In fact, one or more surfaces of many precision parts are ground in order to provide them with the necessary finish, in which high levels of concentration and accuracy are crucial, in order to avoid deviations.

Rectimold, carries out a large part of the grinding process using Manual Surface Grinding Machines. The operation is controlled, in large part, by human operators, as most of the processes are carried out using conventional methods (manual machines).

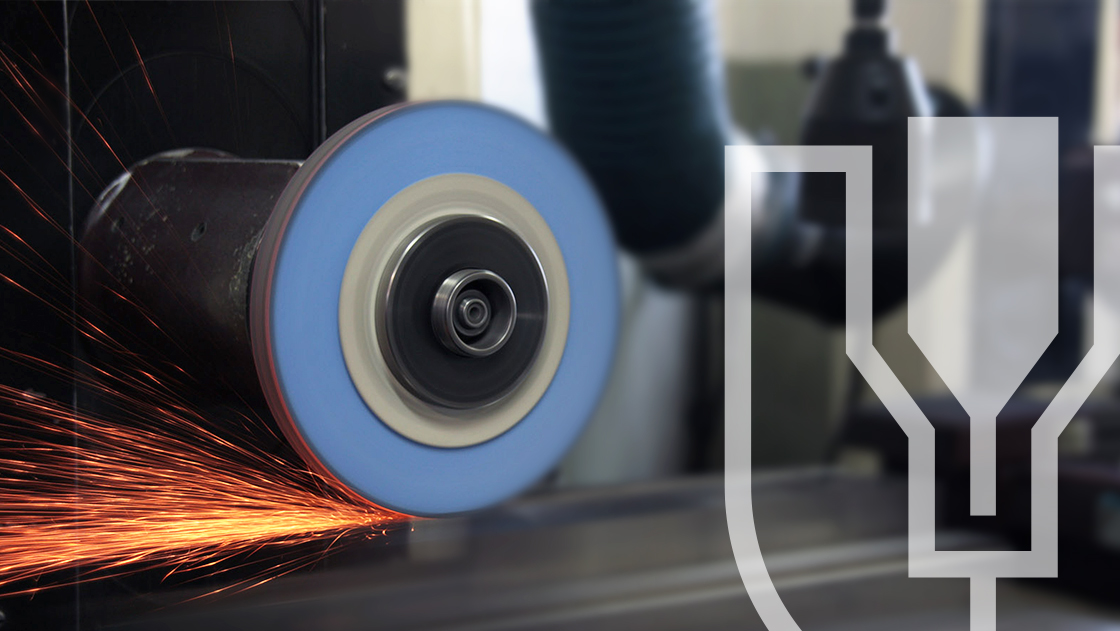

Although there are several types of grinding machines (flat, universal cylindrical and centreless cylindrical), no matter which type is used, these machines specialise in grinding, straightening or exacting, correcting and polishing parts or components. They are therefore machines that work parts in order to give their surfaces greater precision, and to give them a better, cleaner finish.

However, that being said, there is a very specific set of precautions that should be considered in order to achieve successful grinding procedures. These considerations include the choice of grinding machine and its technical characteristics; the care taken to install and maintain the machine; the choice of the type of grinding wheel and its specific purpose; and the shape of the part and material it is made out of.

Given the complexity of the grinding process, Rectimold has ensured that its grinding department is extremely experienced and competent, successfully combining technology with skilled labour in order to obtain parts that achieve greater dimensional accuracy and a cleaner finish.